A cone crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel.

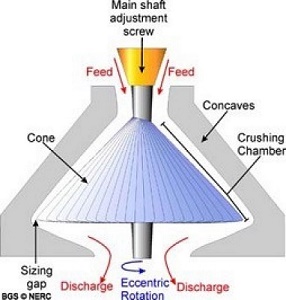

The working principle for cone crusher, Which works by crushing rocks between an eccentrically rotating spindle and a concave hopper. The spindle is powered by a motor, and the movement of the spindle causes the rocks to be crushed against the inner surface of the concave hopper.

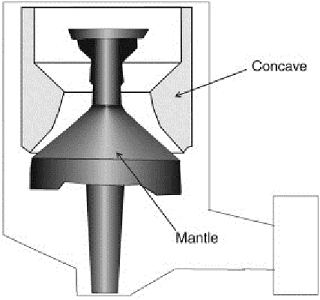

Cone Crusher, it all starts with the material you need to crush, which is known as the feed. The feed drops into the crushing chamber, which is a large circular opening at the top of a cone crusher. Inside the crusher, a moving part which is known as the mantle gyrates inside the machine.

The mantle moves eccentrically, which means that it doesn't travel in a perfect circle. The mantle can swing slightly while it rotates, which continuously alters the gap between the mantle and the concave.

The concave is a fixed ring that's outside of the mantle. As the mantle swings, it crushes the material against the concave. Stones are crushed against each other, which breaks it down further. This concept is known as interparticle crushing.

A cone crusher has two sides: an open side and a closed side. As the material crushes, the particles that are small enough to fit through the open side fall through the space between the mantle and the concave.

As the mantle gyrates, it creates a narrow point and a wide point. The distance on the wide side is known as the OSS or open side setting, while the narrowest point is called the CSS, or closed side setting.

Depending on how the OSS is set, it will determine the size of the particles as they exit the crusher. Meanwhile, since the CSS represents the shortest distance between the concave and the mantle, this is the final crushing zone. How the user configures the CSS is critical for determining capacity, energy consumption and final product size.

Therefore, Cone crushers are widely applied in metallurgical, construction, road building, chemical and phosphatic industry. Cone crushers are suitable for hard and mid-hard rocks and ores, such as iron ores, copper ores, limestone, quartz, granite, gritstone, etc. Type of the crushing cavity is decided by the application of the ores. Standard type is for PYZ (secondary crush); middle type is for PYD (tertiary crush); short-head type is for primary and secondary crush.

Do not hesitate to contact us for all supports that you need or offers for the the crusher parts. WUJING is a global leading supplier for wearing solutions in Quarry, Mining, Recycling, etc, which is is capable of offering 30,000+ different types of replacement wearing parts, of Premium Quality. Averagely extra 1,200 new patterns are added yearly, for fulfiling the increasing demand varieties from our customers. And with annually production capacity of 40,000 tons covers comprehensive range of steel casting products.

Post time: Aug-10-2023