-

Analysis of the Impact of Intelligent Manufacturing on the Precision and Service Life of Crusher Parts

In modern industrial production, crushers, as an important heavy-duty equipment, are widely used in multiple fields such as mining, building materials, and chemical engineering. With the continuous advancement of technology, intelligent manufacturing technology has gradually permeated into the pr...Read more -

Circuit layout design for board distribution: Ensuring the electrical safety of the crusher

In industrial production, crushers are indispensable equipment in many factories, used to break large pieces of materials into smaller particles for subsequent processing and handling. However, the normal operation of the crusher cannot do without the support of the electrical system, and the saf...Read more -

The eccentricity accuracy of the eccentric assembly set: Its influence on the stroke of the crusher

During the operation of the crusher, the eccentric assembly set is one of the key components that determine its core working efficiency. The eccentricity accuracy in the eccentric component set is directly related to the stability and effectiveness of the crusher’s stroke. For scenarios tha...Read more -

The material protection performance of the auxiliary axle box guard cover: How to resist dust and impact

During the operation of the crushing equipment, the auxiliary shaft box guard plays an indispensable protective role. This seemingly simple component actually undertakes the dual mission of defending against dust intrusion and resisting external impacts. Its protective performance directly affect...Read more -

Analysis of the Matching Technology of Thermal Expansion Coefficients between Motors and Conical Sleeves

In modern industrial equipment, the stable operation of crushers cannot be achieved without the precise coordination among various components. Among them, the motor and the conical sleeve, as key components, the matching of the thermal expansion coefficient of their materials is particularly cruc...Read more -

The transmission gear accuracy and power transmission stability of the head assembly

In the operation of various crushing equipment, the head assembly plays a key role in converting power into crushing force. The core of this transformation process lies in the precise fit and coordinated operation of the internal transmission gears. The precision of the transmission gears directl...Read more -

Preventive measures for shrinkage cavities and porosity in high manganese steel wear-resistant castings

For the problem of shrinkage cavities and porosity in wear-resistant castings, comprehensive prevention should be carried out from multiple aspects such as materials, processes and designs. The following are the key measures and detailed explanations: First, optimize the casting process design 1....Read more -

Sturdy protection: Lock nuts suitable for MP series cone crushers

In the processing of various ores and the production of construction aggregates, cone crushers are the core equipment to ensure efficient crushing operations. One of the key components that ensures the stability of its internal structure and its ability to withstand continuous high-intensity vibr...Read more -

How does the combustion ring prevent the main shaft from deforming?

During the operation of the crusher, the main shaft, as one of the core components, its stability and integrity are crucial for the normal operation of the equipment. As an important component in the crusher, the combustion ring plays an indispensable role in preventing the deformation of the mai...Read more -

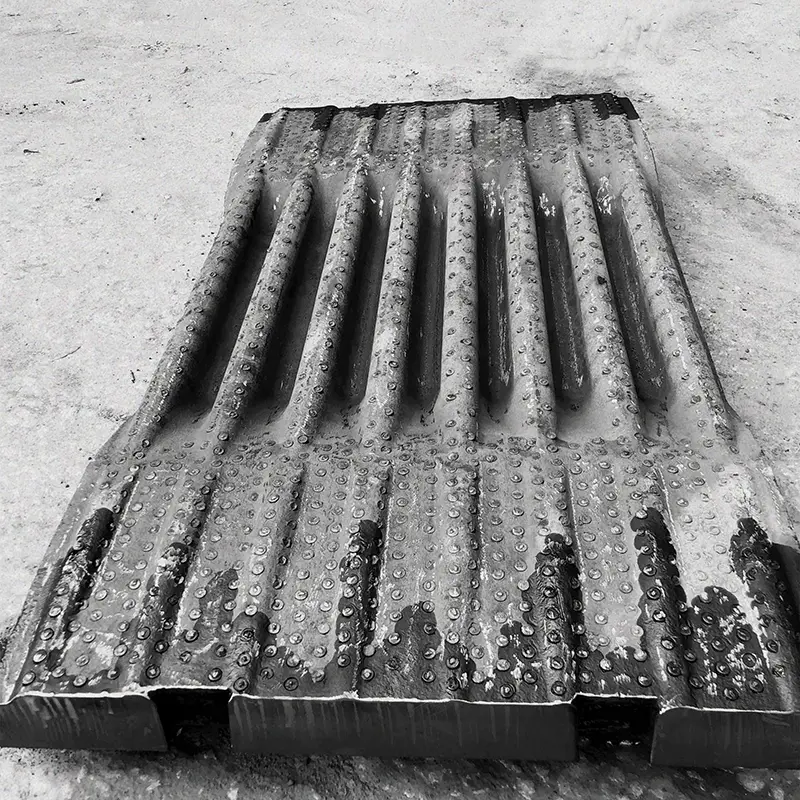

Crushing wall and mortar wall: Solid guardians in the gyratory crusher

On the front line of ore crushing, there are two unsung but crucial components – the crushing wall and the mortar wall. They are like well-coordinated dance partners, working together at high speed to fulfill the mission of crushing raw materials into the required specifications. Understand...Read more -

Heat treatment process of crusher hammer heads: The perfect balance of hardness and toughness

During the continuous operation of the crusher, the hammer heads are subjected to tremendous impact and wear. How can a common metal material be made to have sufficient hardness to resist wear and tear as well as good toughness to withstand impact? This relies on precise heat treatment processes ...Read more -

The coordinated operation of the motor and the V-belt pulley

The motor and the V-belt pulley are two key components in the transmission system of the crusher. Their coordinated operation ensures the normal operation of the crusher. This article will explore the relationship between the motor and the V-belt pulley, as well as how to ensure a good fit betwee...Read more