In the world of industrial manufacturing, the cost of raw materials is a critical factor that influences the pricing and profitability of products. For the crusher parts industry, fluctuations in the prices of key materials like high-manganese steel and chromium iron can have significant implications for both production costs and pricing strategies.

The Role of High-Manganese Steel and Chromium Iron

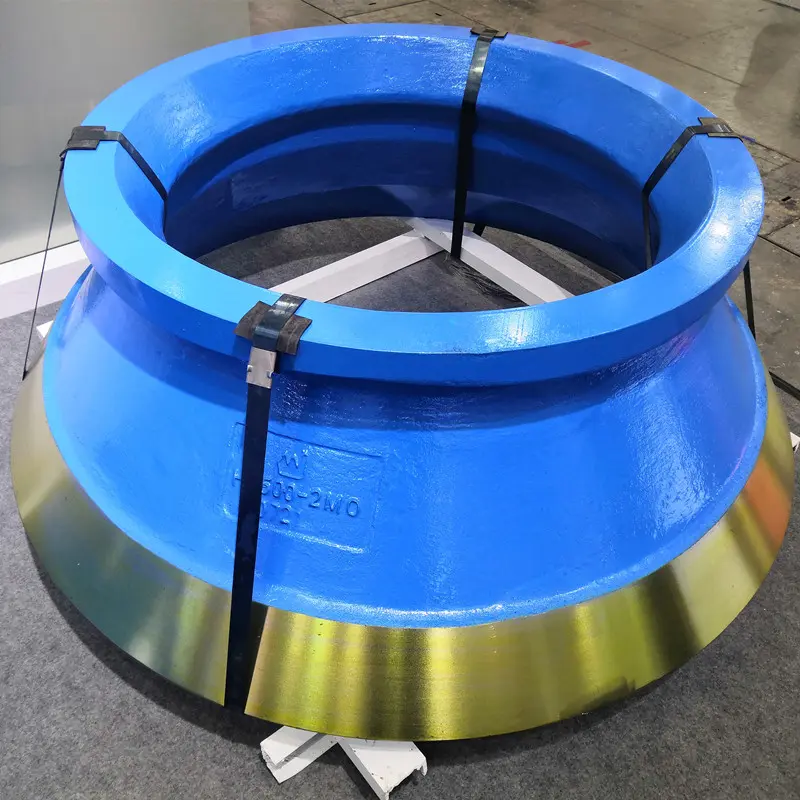

High-manganese steel and chromium iron are essential materials in the production of crusher parts. High-manganese steel is renowned for its excellent wear resistance and toughness, making it ideal for components that endure high stress and abrasive conditions, such as the liners and hammers in crushers. Chromium iron, on the other hand, enhances the hardness and corrosion resistance of steel, contributing to the durability of critical parts.

The Impact of Price Fluctuations

Rising Costs

In recent years, the prices of high-manganese steel and chromium iron have experienced notable fluctuations. According to industry reports, the price of high-manganese steel has seen multiple increases, with significant impacts on the production costs of crusher parts. For example, between 2022 and 2023, the price of high-manganese steel rose sharply, leading to a substantial increase in the cost of manufacturing key components. Similarly, chromium iron prices have also been subject to volatility, influenced by factors such as supply chain disruptions and changes in global demand.

Cost Structure Analysis

The cost structure of crusher parts is heavily influenced by the prices of these raw materials. In 2023, research indicated that raw materials accounted for a significant portion of the total production cost, with high-manganese steel and chromium iron being major contributors. For instance, the cost of high-manganese steel used in the production of wear-resistant liners can represent a large share of the overall cost, making it crucial for manufacturers to monitor and manage these costs effectively.

Pricing Strategies in Response to Fluctuations

Dynamic Pricing

To cope with the volatility in raw material prices, manufacturers often adopt dynamic pricing strategies. This involves adjusting prices based on the current market conditions and the cost of raw materials. When the prices of high-manganese steel and chromium iron rise, manufacturers may need to increase the prices of their products to maintain profitability. Conversely, when raw material prices fall, they may have the opportunity to reduce prices or offer more competitive deals to customers.

Long-Term Contracts

Another strategy to mitigate the impact of price fluctuations is to enter into long-term contracts with suppliers. By securing stable supply agreements, manufacturers can lock in prices for a certain period, reducing the risk of sudden cost increases. This approach helps in stabilizing production costs and allows for more predictable pricing strategies.

Value-Added Services

In addition to adjusting prices, manufacturers can also focus on adding value to their products. By offering enhanced features, improved durability, or better after-sales service, they can justify higher prices and maintain customer loyalty. For example, incorporating advanced wear-resistant technologies or providing comprehensive maintenance packages can differentiate products in the market.

Conclusion

The fluctuating prices of raw materials like high-manganese steel and chromium iron pose challenges for the crusher parts industry. However, by adopting strategic approaches such as dynamic pricing, securing long-term contracts, and adding value to products, manufacturers can navigate these challenges effectively. Understanding and managing the impact of raw material price fluctuations is essential for maintaining competitiveness and ensuring sustainable growth in the industry.

Post time: Oct-15-2025