Heat Treatment Processes: How Quenching and Tempering Significantly Enhance the Hardness and Toughness of Wear-Resistant Steel

When faced with a batch of brand-new jaw plates or hammer heads, what’s the last thing you want to hear? Is it a customer complaint about “insufficient hardness and excessive wear,” or the bad news from the field that “the parts are too brittle and have cracked again”? These seemingly contradictory failure modes—excessive wear and unexpected fractures—are precisely indicative of an imbalance in the performance of wear-resistant steel components. The root cause often lies not in the steel’s chemical composition, but in the heat treatment process that ultimately determines its service performance. Crucially, the core steps of quenching and tempering directly dictate whether a wear-resistant part becomes a “battle-hardened warrior” or a “glass knight.” This article will dissect how precisely controlled quenching and tempering can enhance hardness while imparting essential toughness to steel, thereby producing reliable components that are both wear-resistant and impact-resistant. Whether you’re a purchaser selecting materials or a manufacturer optimizing processes, you’ll find key insights to avoid pitfalls and boost product competitiveness.

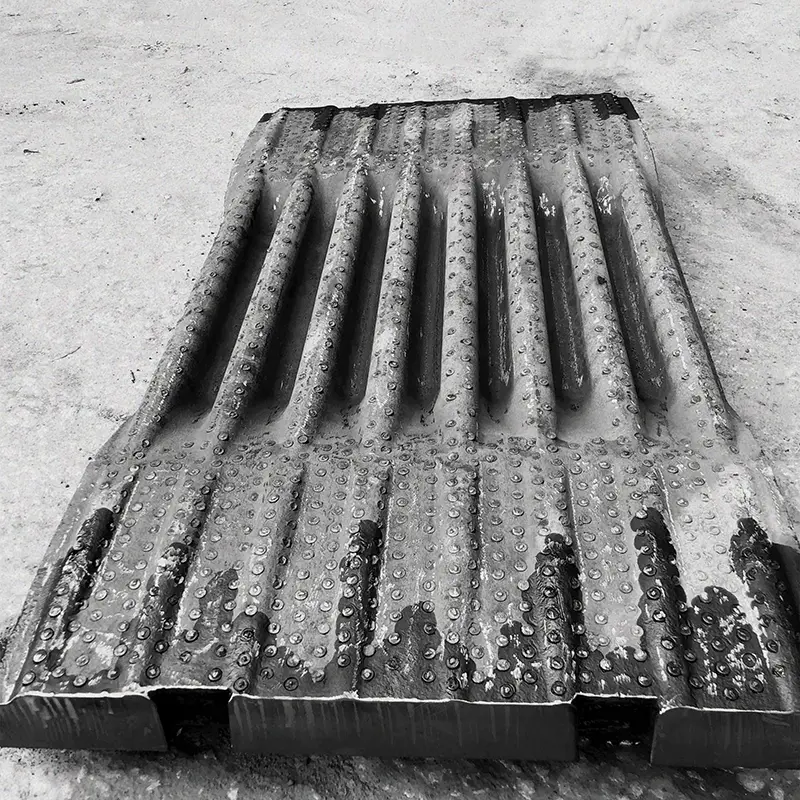

Quenching: The “Tempering” Journey That Bestows Ultra-High Hardness

Simply put, the quenching process involves heating steel above its critical temperature (transforming its internal structure into austenite) and then rapidly immersing it in a quenching medium like water, oil, or polymer solutions for swift cooling. This “shock cooling” prevents the formation of softer pearlite or ferrite phases, instead forcing the steel to crystallize into an extremely hard yet brittle structure known as martensite.

Imagine it like the moment when a red-hot sword blade is plunged into cold water during forging. This instantaneous cooling locks the atoms in their highly active state, creating a highly tense crystal structure—the direct source of its exceptional hardness. For wear-resistant steels—such as high-manganese steel or alloy steels commonly used in crusher liners—hardness after quenching can easily exceed HRC 55, providing the foundation for wear resistance. However, pure martensite behaves like a piece of hard glass: extremely tough yet prone to shattering at the slightest impact. At this stage, the component possesses exceptional wear potential but is highly brittle, unable to withstand any shock or vibration. A common question arises: “Does the choice between water and oil as quenching media make a significant difference?” Water offers the fastest cooling rate and highest achievable hardness but carries the greatest risk of cracking. Oil provides gentler cooling, reducing stress and deformation, though hardness may be slightly lower. The specific choice requires precise calculation based on steel composition and component geometry—there is no absolute answer.

Tempering: The Artistic Balance Between Hardness and Toughness

If quenching makes steel “uncommonly tough,” then tempering is a masterful “harmonization.” It involves reheating the quenched steel to a specific temperature below the critical point (typically between 150°C and 600°C), holding it for a period, and then cooling it in air or by controlled means.

This process is far from simple annealing or softening. Its core function lies in: eliminating the immense internal stresses generated by quenching and transforming unstable brittle martensite into a tough microstructure known as “tempered martensite” or “tempered sorbite.” During this transformation, supersaturated carbon atoms precipitate as fine carbides and distribute uniformly throughout the structure. Consequently, the material’s toughness (impact resistance) and plasticity (deformation capacity) are significantly restored. While hardness decreases slightly, it remains at a very high level. This is akin to weaving a dense elastic network within hard glass, enabling it to resist scratches while absorbing energy through micro-deformation upon heavy impact, rather than shattering immediately. While servicing a major mining client, we conducted failure analysis on their cone crusher bowl liners. We discovered that the fractured components had a hardness as high as HRC62 but extremely low impact energy. After advising the supplier to optimize the tempering process, the hardness was adjusted to HRC58-60, resulting in over a 30% increase in impact toughness and a 20% longer service life.

Process Parameters: How Do Temperature, Time, and Quenching Medium Affect Wear-Resistant Component Performance?

Understanding the principles of quenching and tempering reveals that the final properties of wear-resistant components are not fixed values but precisely controlled outcomes of heat treatment parameters. These three critical variables determine a component’s “character”:

1. Quenching Temperature and Medium:

- Too low: Incomplete microstructural transformation, insufficient hardness. Excessively high temperatures result in coarse grain structure and brittle properties. The choice of quenching medium directly affects cooling rate, thereby influencing the extent of martensitic transformation and internal stress levels. For example, in complex-shaped plate hammers with significant cross-sectional variations, graded quenching or isothermal quenching (briefly holding in salt baths or hot oil before cooling) effectively prevents cracking.

2. Tempering Temperature:

This is the most critical control parameter. Low-temperature tempering (150-250°C) primarily relieves stress while retaining most hardness, suitable for high-wear, low-impact applications like conveyor liner plates. Medium-temperature tempering (350-500°C) significantly enhances elasticity and toughness while maintaining good hardness, commonly used for spring steels. High-temperature tempering (500-650°C) produces tempered sorbite with excellent comprehensive mechanical properties, offering the optimal balance of strength and toughness. It is suitable for critical structural components subjected to complex stresses, though hardness decreases significantly.

3. Holding Time:

Ensures sufficient diffusion of heat and atoms, enabling uniform and complete microstructural transformation. Insufficient time results in substandard core properties; excessive time may cause grain growth or excessive softening.

A vivid case study involves jaw crusher tooth plates both manufactured from Mn13 high-manganese steel. One manufacturer employed traditional water quenching (a type of solution treatment), while another adopted an improved process of “water quenching + low-temperature tempering.” The latter maintained high wear resistance while significantly enhancing fracture resistance, achieving over 15% longer overall service life under harsh granite crushing conditions.

From Process to Quality Control: How Purchasers Identify High-Quality Heat-Treated Wear Parts?

As a purchaser or equipment maintenance manager, you cannot directly intervene in the heat treatment furnaces on the production line. However, you can assess a supplier’s heat treatment process control capabilities through several key points to select high-quality wear-resistant steel components:

• Request material and heat treatment reports: Reputable suppliers should provide material certification (e.g., GB, EN, ASTM standards) and detailed heat treatment process curve reports (including at least quenching/tempering temperatures, times, and media). This represents the fundamental technical threshold.

• Focus on the correlation between hardness and impact energy: Avoid evaluating solely based on hardness. Inquire about the room-temperature impact energy (Akv or J-value) for critical components (e.g., hammer heads, plate hammers, jaw plates) within a specific hardness range (e.g., HRC 58-62). An excellent process maintains substantial toughness values even at high hardness levels.

• Inspect component metallographic structure: For bulk or critical purchases, request metallographic photos or submit samples for testing. Under microscopy, high-quality heat-treated microstructure should exhibit uniform, fine tempered martensite + carbides, free of noticeable network structures, coarse grains, or undissolved ferrite.

• Evaluate surface appearance and dimensional stability: Inspect components for visible quenching cracks (hairline cracks), excessive oxidation/decarbonization, or distortion. Superior heat treatment control minimizes deformation, reducing subsequent machining requirements and installation issues.

Remember, a stable, traceable heat treatment process delivers far greater value than merely using “premium” materials. It provides your equipment with enduring, reliable operational assurance, along with lower crushing costs per ton of material and reduced downtime risks.

In summary, quenching and tempering are not merely sequential steps of “hardening followed by softening,” but a precisely coordinated “performance forging system.” Quenching furnishes wear-resistant steel with armor against abrasion, while tempering infuses this armor with a resilient soul—enabling it to withstand both grinding erosion and impact forces under harsh conditions. Understanding and prioritizing this process is the essential path to elevating crusher components from “adequate” to “exceptional.”

FAQ (Frequently Asked Questions)

1. Q: Does higher tempering temperature always improve toughness but reduce hardness?

A: This is the general trend, but the relationship isn’t linear. Within the low-temperature tempering range (e.g., 200-300°C), hardness decreases slowly while toughness improves significantly—a highly cost-effective zone. As temperature rises further, hardness declines more rapidly. An optimal heat treatment strategy involves identifying the tempering temperature that delivers maximum toughness while meeting the target hardness requirement, achieving the best performance balance.

2. Q: The wear-resistant hammer heads we purchased exhibit very high hardness on the working surface, but significantly lower hardness near the mounting holes or on non-working surfaces. Is this normal?

A: This may indicate an abnormal “soft spot” phenomenon, typically caused by two factors: First, uneven cooling during quenching, where the transition zone between thick and thin sections or the core cools insufficiently, preventing complete martensitic transformation. Second, localized areas undergoing subsequent machining (e.g., drilling) without stress-relief annealing or experiencing excessive localized tempering. For critical load-bearing components, hardness uniformity is a vital quality indicator; excessive variation may become a fatigue crack initiation point.

3. Q: How can one quickly determine if a wear-resistant component has undergone proper heat treatment?

A: Beyond reviewing reports, field methods include: 1) Randomly testing critical areas with a hardness tester to verify uniformity and compliance with nominal ranges; 2) Listening carefully—gently tapping the component with a metal rod. Components quenched without tempering or with insufficient tempering typically produce a sharp, brief metallic ring (“steel” sound); while fully tempered components produce a relatively dull, prolonged sound. Of course, professional non-destructive testing and laboratory analysis remain the most reliable methods.

Meta Description: Deep dive into how quenching and tempering synergize in heat treatment processes to significantly enhance the hardness and toughness of wear-resistant steel. This article provides crusher component buyers and manufacturers with process principles, parameter control, and quality control essentials to help select durable, impact-resistant wear parts. Read now to optimize your equipment performance and procurement decisions.

Keywords: Wear-resistant steel heat treatment process, Quenching and tempering hardness and toughness, Crusher component heat treatment, Heat treatment process parameter control, Wear part procurement quality control

Post time: Jan-26-2026