In the daily operation of mines and quarries, cone crushers play a crucial role. As one of the core wearing components of this type of equipment, the quality of the cast steel concave bowl lining directly affects the performance and efficiency of the entire crushing system. This article will provide you with a detailed introduction to the characteristics and functions of this key component in the 7-foot cone crusher, as well as how to select the appropriate lining product.

The core function of the concave bowl lining

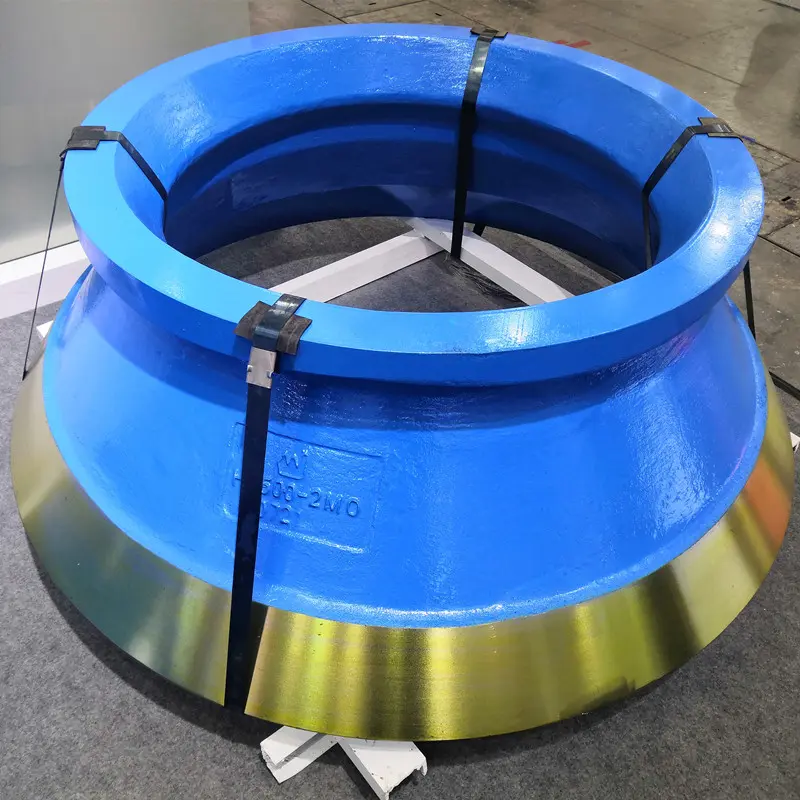

The concave bowl lining is a key component inside the cone crusher. It is installed inside the main body of the crusher and, together with the moving crushing wall, forms the crushing cavity. When the raw materials enter the crushing chamber, the concave bowl lining works in coordination with the crushing wall, breaking the large pieces of materials into the required particle size through extrusion and impact.

This component is called the “wearing part” because it constantly bears the friction and impact of materials during operation. High-quality concave bowl linings can effectively extend the service life of equipment, reduce the frequency of shutdown and replacement, and thereby enhance overall production efficiency. For large equipment like a 7-foot cone crusher, choosing the right lining is particularly important because the replacement process is relatively complex and time-consuming.

The advantages of choosing cast steel materials

The concave bowl lining is usually made of high-strength cast steel materials, and this choice is no accident. Cast steel material has several significant advantages: Firstly, it can withstand huge impact forces and continuous wear and tear; Secondly, through special heat treatment processes, its wear resistance can be further enhanced. Finally, cast steel materials, while ensuring strength, also possess a certain degree of toughness, which can reduce the risk of cracking under extreme working conditions.

The requirements for the lining also vary under different working conditions. For instance, the requirements for lining materials are different when dealing with granite of higher hardness and limestone of relatively softer hardness. Professional manufacturers will adjust the material formula and heat treatment process according to the actual application scenarios of customers to achieve the best wear resistance effect.

The importance of design and installation

The design of the concave bowl lining also affects the performance of the crusher. An excellent design should take into account multiple factors such as the flow characteristics of materials, the distribution of crushing force, and the convenience of replacement. A reasonable curve design can optimize the material flow path, reduce energy loss, and ensure the uniform particle size of the crushed product at the same time.

The installation process should not be ignored either. Even the highest quality linings, if not installed properly, may lead to premature wear or poor performance. Correct installation should ensure that the lining fits perfectly with the main unit and that all fixed points are evenly stressed. For large equipment like a 7-foot cone crusher, it is recommended that it be installed by experienced technicians and inspected with professional tools.

Judgment on the timing of maintenance and replacement

In daily operation, regularly checking the wear condition of the concave bowl lining is an indispensable maintenance task. Operators should establish a regular inspection system and record the wear progress of the lining. By observing the wear patterns and degrees, not only can it be determined when replacement is needed, but also potential operational issues such as uneven feeding or improper equipment adjustment can be identified.

Determining the timing of replacement requires a comprehensive consideration of multiple factors: the remaining thickness of the lining, the quality changes of the crushed products, the changes in the operating current of the equipment, etc. Replacing too early will increase operating costs, while replacing too late may affect product quality or even damage other components. Experienced operators can often make a preliminary judgment on the wear condition of the lining by observing the changes in the crushing sound and the discharge situation.

Post time: Aug-15-2025