Bearing Seizure Again? Don’t Blame Only the Lubricant—The Problem May Lie in the “First Line of Defense”

In the crusher industry, the most frustrating issue is not low output, but unplanned downtime. In particular, damage to core rotating components—bearings and sleeves—is often the culprit behind sudden production line outages. When this happens, the first reaction of most on-site maintenance workers is to check if the lubricant is sufficient or contaminated. However, based on our over a decade of experience working with hundreds of sand and gravel yards and mines, over 70% of premature bearing failures stem from the intrusion of external contaminants, especially dust. No matter how advanced the lubrication system is, it cannot withstand pervasive dust turning the lubricant into an abrasive paste. Today, we’re not talking about lubricants themselves, but focusing on the “armor” outside them—the sealing system of crusher parts. Though unassuming in appearance, it is a critical factor that determines equipment lifespan and impacts your total cost of ownership (TCO). We will break down how to build a truly reliable defense line to protect your expensive bearings and sleeves from three perspectives: design, material selection, and maintenance.

1. Labyrinth or Lip Seal? Practical Selection Logic for Different Sealing Types

When purchasing or replacing seals, how do you choose between the two mainstream options—labyrinth seals and lip seals (oil seals)? This is not simply a matter of price, but a matching decision based on operating conditions.

Lip Seals (Oil Seals)

The king of static sealing, yet vulnerable to movement and contamination. Lip seals work by using an elastic rubber lip to cling tightly to the shaft journal for sealing. Their advantage is an excellent initial sealing effect, which effectively prevents lubricant leakage. However, they have two “natural enemies”: first, radial runout of the shaft journal—excessive runout causes rapid wear of the lip; second, external dusty environments—tiny hard particles can embed themselves in the lip, continuously abrading the shaft journal and damaging the seal like sandpaper. Therefore, lip seals are more suitable for applications with relatively clean working environments, precisely controlled shaft runout, and moderate rotational speeds, such as the drive shaft seals of some small and medium cone crushers.

Labyrinth Seals

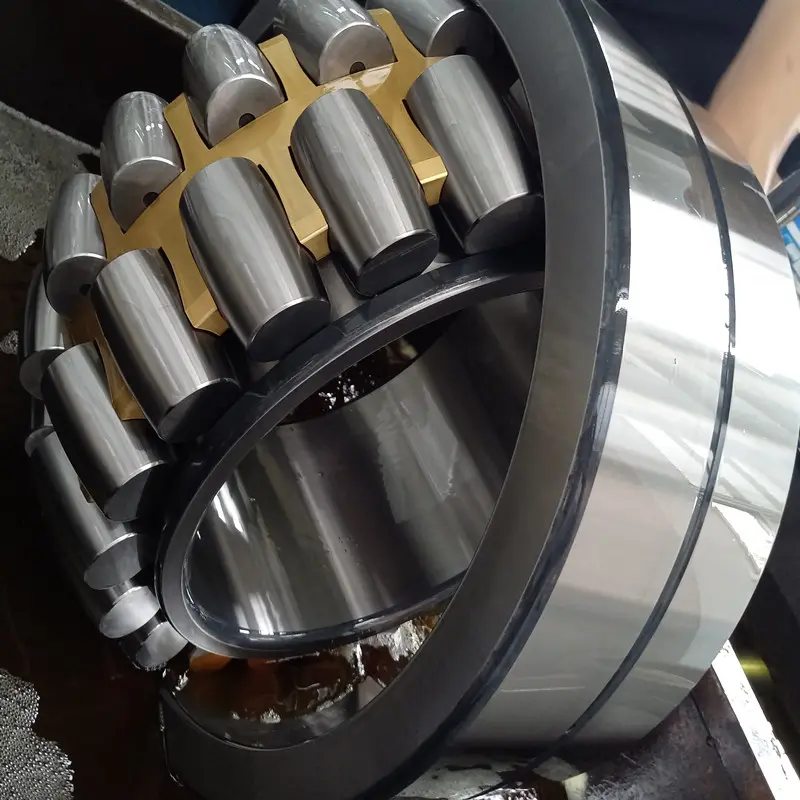

Built for high-dust, high-speed conditions. Labyrinth seals operate on an entirely different principle: instead of relying on contact and friction, they feature a series of continuous, tortuous annular gaps and cavities between rotating and stationary components. This is analogous to the “barbican” of ancient city walls—for dust to intrude, it must change direction and speed multiple times, and is ultimately thrown out by centrifugal force or falls into the oil return groove under gravity. Their greatest advantage is contact-free, zero-wear operation with an extremely long service life, making them highly adaptable to harsh working conditions with slight shaft eccentricity or vibration. Thus, labyrinth seals are almost the only reliable choice for high-dust, high-impact vibration areas such as the main bearings of jaw crushers and the rotor bearings of large impact crushers.

A Real Case of Failed Sealing Selection

A large granite crushing production line in East China originally adopted high-end imported double-lip oil seals for the rotor bearings of its impact crushers. Within three months of operation, oil leakage and abnormal bearing noise occurred frequently. Inspections revealed that the shaft journal surface had been grooved by dust, and the oil seal lips were damaged—the on-site dust concentration far exceeded the design tolerance of the oil seals. Later, we revised the sealing solution to a combination of multi-channel labyrinth seals + a small amount of positive pressure air purge. Although the initial modification cost was slightly higher, no bearing failures caused by sealing issues occurred in the following three years, saving hundreds of thousands of yuan in spare parts and downtime losses alone.

You may ask: Is there a solution that combines the advantages of both?

Absolutely—and this is also the development trend of current high-end equipment: combined seals. The most common type is “outer labyrinth seal + inner lip seal”. The labyrinth seal blocks the vast majority of coarse particle dust and rainwater, creating a relatively clean working environment for the internal oil seal; the oil seal is responsible for the final, tight lubricant sealing. This design balances reliability and oil leakage prevention, but features a relatively complex structure and higher requirements for installation accuracy.

2. Materials and Details: The Easily Overlooked “Seal Killers”

Choosing the right sealing type is only half the battle. The material of the seal itself, as well as the supporting “small details”, often determine the final success or failure.

Rubber Lip Seals: Temperature, Oil, and Wear Resistance—None Can Be Compromised

Crushers operate under large temperature differences and with a variety of lubricants. Therefore, sealing rubber must simultaneously possess excellent high and low temperature resistance (e.g., -40°C to +150°C), mineral oil/synthetic oil resistance, and good wear resistance. Nitrile rubber (NBR) is a universal choice with high cost-effectiveness; however, for high-temperature conditions or special greases, fluororubber (FKM/Viton) may be required, which offers superior temperature and chemical resistance but comes at a higher cost. When purchasing, be sure to specify the material to the supplier and request material certification.

The “Achilles’ Heel” of Labyrinth Seals: Clearances and Airflow

The performance of labyrinth seals is extremely dependent on the preset radial and axial clearances in the design. Excessively large clearances allow unimpeded dust intrusion; excessively small clearances may cause friction or even seizure due to thermal expansion or slight deformation. Excellent designs determine the optimal clearances through precision machining and thermal expansion calculations. A more advanced approach is to introduce micro positive pressure air sealing: filtered clean air with a pressure slightly higher than the outside (usually only a few dozen Pascals) is introduced into the labyrinth channels to form an air curtain that actively “blows away” dust. This application yields remarkable results on the main shafts of vertical shaft impact crushers (sand makers) with extremely high sealing requirements.

The Overlooked “Accomplices”: Breather Vents and Oil Seal Housings

Bearing housings are not completely sealed—thermal expansion and contraction of lubricants create a “breathing” effect. A clogged or poorly filtered breather vent will form negative pressure inside the bearing housing, which instead sucks in external dust-laden air like a vacuum cleaner. Similarly, if the housing bore for installing the oil seal has insufficient machining accuracy, burrs, or out-of-roundness, it will directly cause the oil seal to twist, leading to uneven stress on the lip and premature failure. These details must be inspected together when purchasing complete parts or maintenance kits.

You may ask: We purchased well-known brand seals—why do they still fail quickly?

The problem is most likely not the seals themselves, but the installation process. Rough hammering, failure to use special installation tools, not applying grease to protect the lip, inadequate cleaning of the housing bore—any non-standard operation can cause a high-quality seal to start working “with injuries” the moment it is installed, drastically reducing its service life.

3. Maintenance Philosophy: Treat the Sealing System as a Subsystem Requiring “Active Management”

The sealing system is not a “fit-and-forget” component. Establishing the correct maintenance concept can extend its service life several times over.

Key Inspection Steps: Observe, Listen, Touch

During daily inspections, in addition to checking for oil leakage, pay closer attention to whether there is abnormal dust accumulation in the sealing area (which may indicate clogged labyrinth channels) and whether there is abnormal noise or high temperature caused by friction. Touch the part of the bearing housing near the seal to feel for abnormal temperatures.

Lubrication Management is a Seal’s Ally

Proper lubrication protects not only bearings but also seals. Maintaining the correct oil level (neither too low to cause dry friction of the seal nor too high to create excessive pressure), using clean, correctly specified lubricants, and filtering or replacing them regularly can all reduce the load on the seal. For grease-lubricated parts, use high-quality grease with good seal compatibility, and inject it quantitatively at strict intervals to prevent hardening of old grease from clogging the seal lip.

Establish a Standard Operating Procedure (SOP) for Seal Replacement

Seal replacement should not be an impromptu emergency repair, but part of a preventive maintenance plan. In equipment operation records, track the root cause of each seal failure (wear, aging, or installation issues?) and determine a reasonable replacement cycle accordingly. When replacing seals, be sure to use original or equivalent quality spare parts, and ensure a clean and professional installation environment.

You may ask: Is there a “permanently maintenance-free” seal?

With current technology, no mechanical seal has an infinite service life under the extremely harsh working conditions of crushers. Our goal is to maximize the service life of the sealing system through scientific design, correct selection, and active maintenance, matching it to the major overhaul cycle of bearings. This achieves planned downtime and avoids sudden failures—the most cost-effective strategy for protecting bearings and sleeves.

Conclusion: The Value of Sealing Lies in Turning Uncertainty into Certainty

In crushing production lines, time is the greatest cost. The value of a reliable sealing system is far more than the price of a few rubber rings or metal rings. Its core value is to physically isolate the most uncontrollable external environment (dust, moisture) from the most precise internal components (bearings, sleeves), turning the “uncertainty” of equipment operation—i.e., sudden failures—into predictable, planned maintenance cycles. It protects not only bearings, but also the continuity of the entire production line and your return on investment. Next time you struggle with short bearing service life, take a close look at that seemingly simple line of defense. Building and maintaining this defense line is the key to keeping your crusher running stably even in a dust-filled environment.

FAQ: Frequently Asked Industry Questions

Q1: Our crushers operate in a highly humid environment (wet production)—what special considerations should be made for the sealing system?

Moisture is more problematic than dry dust, as water can cause lubricant emulsification and metal corrosion. In this case, the sealing solution should focus on:

- Materials: Prioritize sealing materials with better water and corrosion resistance, such as fluororubber (FKM).

- Design: Adopt multi-channel labyrinth seals and design effective drainage holes/grooves to allow intruded water to drain quickly instead of accumulating in the seal cavity.

- Auxiliary Measures: Consider filling the bearing housing with high-performance waterproof grease as an additional barrier.

Q2: The original seal of an old piece of equipment has poor performance—how to carry out effective modification and upgrading?

Seal upgrading for old equipment is a highly cost-effective investment. The typical steps are:

- Evaluation: Confirm whether the dimensional accuracy and wear condition of the existing bearing housing and shaft journal support the installation of new seals.

- Selection: If space permits, prioritize upgrading to labyrinth seals or a “labyrinth + lip seal” combination. If space is limited, consult a professional supplier to select a customized oil seal with a wider cross-section, auxiliary lip, or multi-spring reinforced design.

- Machining and Installation: Local machining of the housing bore or installation of supporting seal covers may be required—be sure to have the work performed by experienced technicians.

Q3: How to judge potential sealing system failure in advance through daily monitoring?

Pay attention to the following early warning signs:

- Lubricant Condition: Regular sampling and observation—abnormal darkening, turbidity, or dust deposition at the bottom of the lubricant indicates a decline in sealing performance.

- Bearing Housing Temperature: A continuous temperature rise at the same location compared to historical normal values may signal increased friction (over-tight or damaged seals) or poor lubrication.

- External Observation: A small amount of regular, uniform oil marks around the seal may be normal, but jet-like oil contamination or large clumps of dust adhesion requires immediate inspection.

Establishing data records for these key points is the foundation of predictive maintenance.

Meta Description

An in-depth analysis of how crusher sealing systems effectively block dust and protect core bearings and sleeves. This article provides a practical guide from seal type selection, material details to maintenance strategies, helping buyers and equipment managers extend component service life, reduce unplanned downtime, and achieve cost reduction and efficiency improvement. Read now for a professional protection solution.

Keywords

crusher sealing system, bearing dust seal, crusher labyrinth seal, crusher parts maintenance, lubrication system contamination prevention

Post time: Feb-06-2026